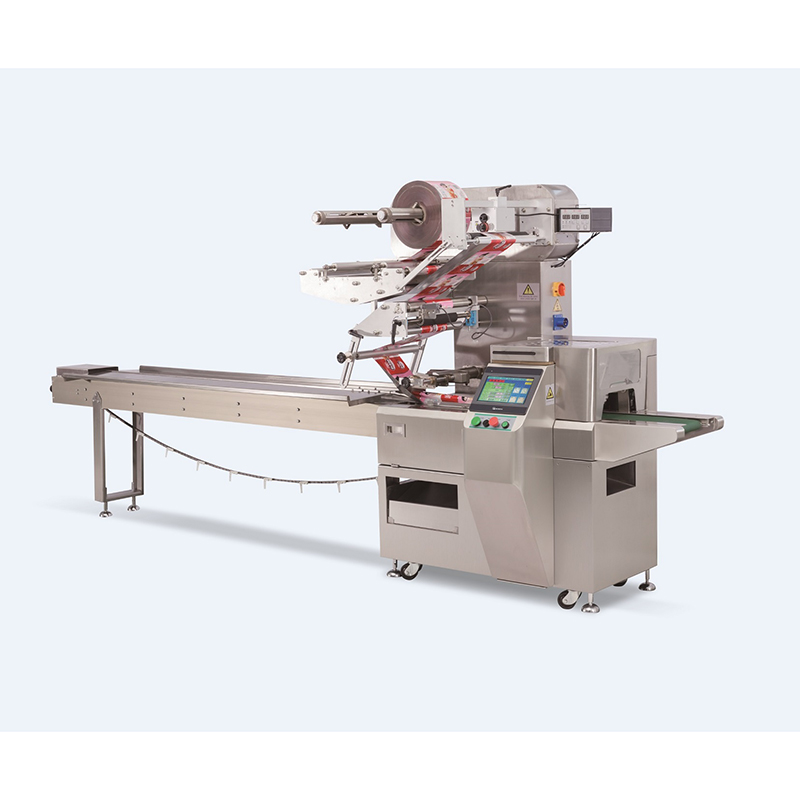

100% Original Factory Candy Packing Machine - TMZP3000S Flow Wrapper Pillow Packing Machine (Servo control, Bottom Film type) – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

100% Original Factory Candy Packing Machine - TMZP3000S Flow Wrapper Pillow Packing Machine (Servo control, Bottom Film type) – Temach Detail:

Product Advantages

1. The plastic film packaging equipment detects and sets bag length automatically.

2. The pillow-type packing machine easy to maintain or change location, guaranteeing long life span and hygienic.

3.The single chip of main control circuit developed by our company.

4. Digital screen and transducer control the wrapping machine, to make sure operation conveniently.

5. Double transducer control with stepless speed shift and wide adjustment, It can match well with the former working procedure of production line;

6. The flow pack machinery automatically and accurately monitors the whole procedure by highly sensitive sensors

7. With menu storage and memory function, the controller can save multiple sets of parameter configurations, and when the product or packaging film is changed, the formula can be used by calling out on the touch screen.

8. The industry-leading electronic cam algorithm, the bag length range is 90mm — unlimited length, the bag length is set and cut immediately, in one step, saving time and film.

9.Advanced electronic anti-cutting, electronic anti-aircraft bag algorithm. The feed detection electric eye will automatically position the product, and the empty material film will stop, saving packaging materials.

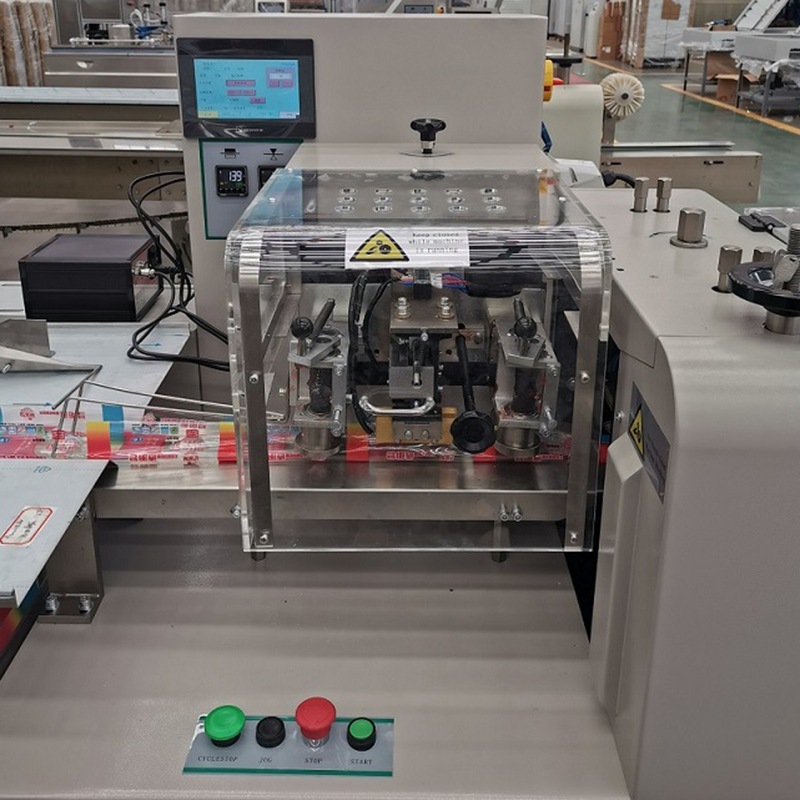

10. Horizontal sealing, vertical sealing, and feeding are all controlled by independent servo motors, with simple mechanical structure, stable operation, and low noise.

11. Man-machine interface, convenient and quick parameter setting, automatic tracking of color code, automatic correction of cutting length. Digitally input the sealing and cutting position to make the sealing and cutting position more accurate.

12. The fault is automatically diagnosed, and the fault display is clear at a glance.

13. Automatic centering single support paper, well-known brand servo motor / PLC/touch screen This is a stand-alone standard configuration.

14. Inflatable, alcohol spray, anti-cutting material, coding machine, discharging brush, stainless steel are optional for a single machine.

15. The standard horizontal sealing cutter shaft center distance is 132 double cutters, and the cutter distance can be changed to 114 or 90. According to the actual size of the product, when the product is small and the required packaging speed is high, the cutter distance 114 or 90 can be selected.

Technical Parameter

| Model | TMZP3000S (Belt type/Chain type) |

| Speed | 35~150 pcs/min Automatic Feeding10~60 pcs/min Manual Feeding type |

| Bag Size | (L)90mm- no Limit, (W)30-140mm, (H)5-50mm |

| Film Width | 65-400mm |

| Film Material | OPP/CPP,PT/PE,KOP/CPP,ALU-FOIL |

| Heating | 3.8kw |

| Motor | 2.5kw |

| Total Power | 6.3kw |

| Weight | 630kg |

| Dimension | (L)4000mmX(W)960mmX(H)1400mm |

Display

Product detail pictures:

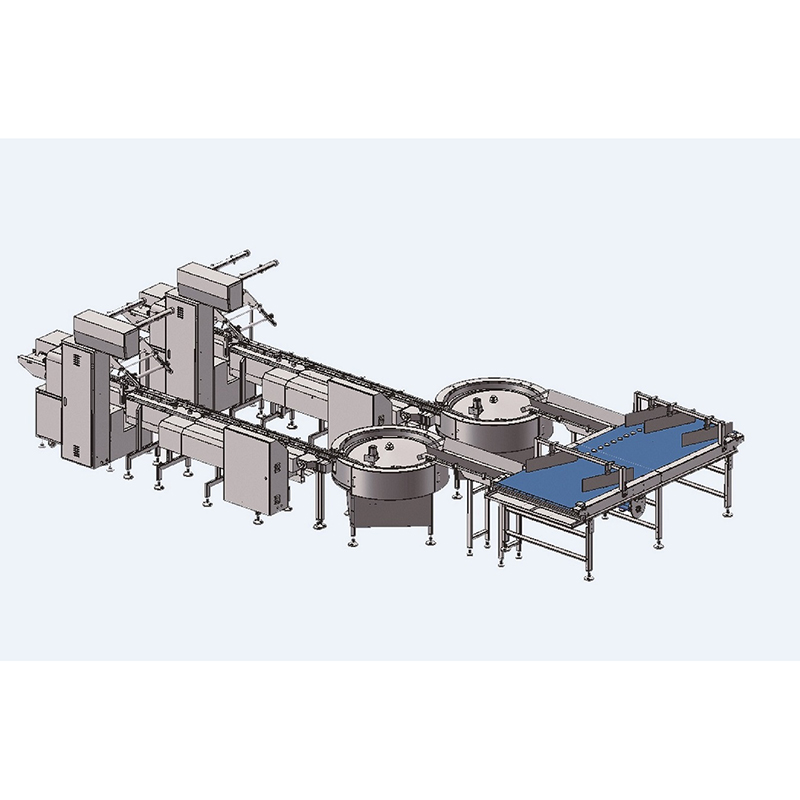

Related Product Guide:

Our organization sticks to your principle of "Quality may be the life of your organization, and reputation will be the soul of it" for 100% Original Factory Candy Packing Machine - TMZP3000S Flow Wrapper Pillow Packing Machine (Servo control, Bottom Film type) – Temach, The product will supply to all over the world, such as: Zambia, Surabaya, Mexico, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.