Low MOQ for Food Cartoner - TMZP500SG Flow Wrapper Pillow Packing Machine (Servo control) – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Low MOQ for Food Cartoner - TMZP500SG Flow Wrapper Pillow Packing Machine (Servo control) – Temach Detail:

Basic Introduction

Flow Wrapping or Horizontal Form-Fill and Seal (HFFS) is the process of making a horizontal bag from a single roll of film. Heat is applied to the bottom and ends of the film to form a sealed, flexible package already filled with products. Flow wrap packaging is used for a variety of products from food and bake goods to regular household items and stationery.

Characteristics and Structural Features

1. With menu storage memory function, can use the memory formula from the touch screen according to different products or packaging film.

2. With the industry-leading electronic cam algorithm, bag length range from 60 mm to infinite, The bag’s actual length takes effect immediately after setting, save time, and packaging film.

3. Advanced algorithm for preventing cutting products and empty bags. Packaging film stops feeding when no product, save materials.

4. The horizontal sealer, vertical sealer, and product feeding are controlled by an independent servo motor. The mechanical structure is simple, the operation is stable and small noise.

5. The packing machine can track the feeding speed automatically when connected with the line. High precision, high speed up to 300 packs/ per minute with double blades.

6. Human-machine interface, the parameter setting is easy and convenient, the color mark can automatically track and correct cutting length. Digital input of cutting position makes the sealing and cutting more accurate.

7. Self failures diagnosis, clear failure display.

8. Automatic alignment of a single paper, well-known brand servo motor / PLC/ touch screen. above these are machine standards.

9. Double film support rollers, automatic film connection, inflatable, alcohol spray, lifting panel, date printer, vertical seal/output brush, fully stainless steel frame. preventing cutting products&empty bags, Above these are machine optional devices.

10. The center distance of the standard horizontal seal knife shaft is 132, which can be changed to 105 or 90 when the product is small and the required packing speed is high (such as 300 packets/min or above).

11. In-feed part can be customized according to actual needs.

12. It can communicate with upstream and downstream machines if needed.

Technical Parameters

| Model | TMZP-500SG |

| Speed | 35~300 pcs/min |

| Bag size | (L)60- no limit (W)30-150mm(H)5-50mm |

| Film Width | 65~400mm |

| Film Material | OPP/CPP, PT/PE, KOP/CPP, ALU-FOIL |

| Dimension | (L)4000mmX(W)960mmX(H)1600mm |

| Heating | 3.8kW |

| Motor power | 2.5kW |

| Total power | 6.3kW |

| Overall weight | 550kg |

FAQs For This Flow Wrappers

Q: If the film used up, do we need to stop the packing machine?

A: If you don’t have the automatic splicing film function, you need to stop the machine and reset the film. If you have, you don’t need to.

Q: What’s the advantage of the automatic splicing film function of the packaging machine?

A: Save time, human operation, and product waste, because you don’t need to slow down or stop the packaging equipment.

Q: Does the packaging machine ZP-500SG has a menu storage memory function?

A: Yes, of course, the packaging machine has a menu storage function. It can save at least 100 sets of formulas.

Q: Which parts of the packaging machine ZP-500SG are controlled by servo motors?

A: The ZP-530S Packaging equipment is controlled by 3 servo motors. So the horizontal sealing, horizontal sealing, and the infeed parts are controlled by servo motors.

Q: Can this packaging equipment ZP-500SG connect with a fully automatic packaging system?

A: Yes, and the speed of the packing machine ZP-530S can up to 300 bags per minute for small products.

Q: What’s the optional configuration of the ZP-500SG?

A: First, servo motor quantity can be customerized. Single-servo motor, double servo motors, or 3 servo motors controlled.

Second, outfit the material of the packaging machine. Standard is painted steel. 304 stainless steel is optional.

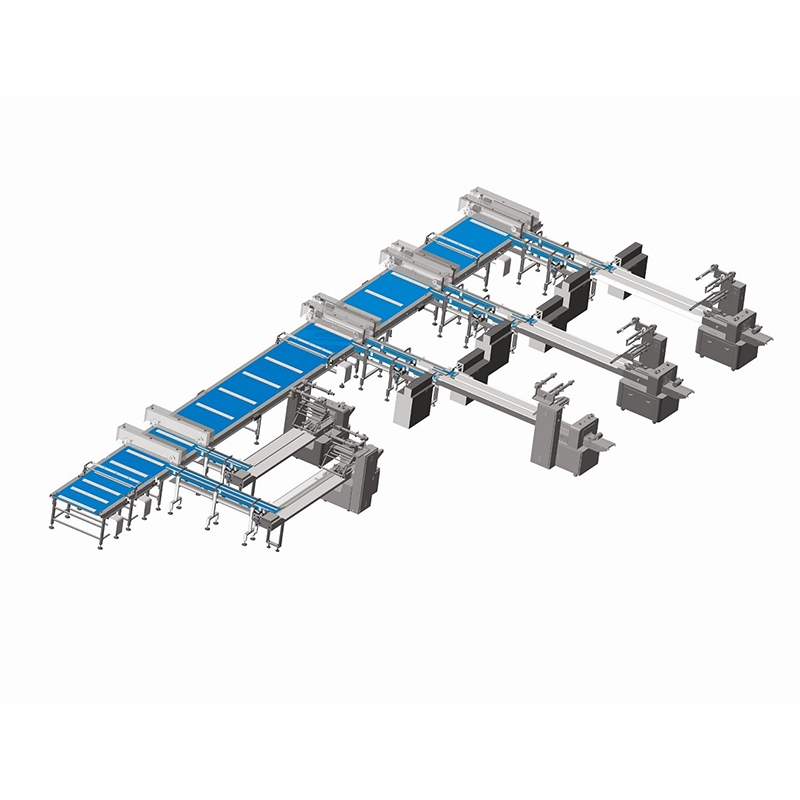

Display

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for Low MOQ for Food Cartoner - TMZP500SG Flow Wrapper Pillow Packing Machine (Servo control) – Temach, The product will supply to all over the world, such as: Zimbabwe, Finland, Johannesburg, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!