Manufacturing Companies for Press And Seal Machine - TMZP100 Flow Wrapper Pillow Packing Machine – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Manufacturing Companies for Press And Seal Machine - TMZP100 Flow Wrapper Pillow Packing Machine – Temach Detail:

Technical Parameters

| Model | TMZP-100 |

| Speed | 35~220 pcs/min |

| Bag size | (L)65- 200mm(W)30-90mm(H)5-30mm |

| Film Width | 65~220mm |

| Film Material | OPP/CPP PT/PE KOP/CPP ALU-FOIL |

| Dimension | (L)4000mmX(W)850mmX(H)1600mm |

| Heat power | 2.4kW |

| Motor power | 0.6kW |

| Total power | 3kW |

| Overall weight | 550kg |

TMZP-100 Horizontal Packaging Machine with High Speed and CE

1.Product introduction

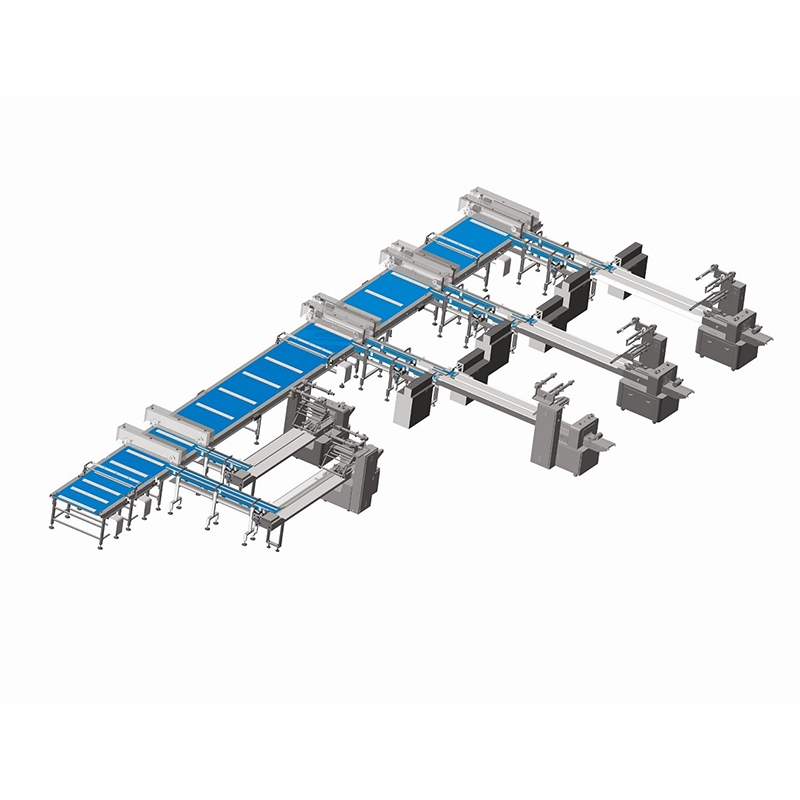

This flow wrapping machine is the first invented model with 220 bags per minute stable speed, designing for small products, such as cake , biscuit, tissue, hardware parts

Automatic machines for high productions. Horizontal packing using a single film coil with three weldings : two cross-weldings and one longitudinal welding. This type of packaging machine is aimed at food and non – food markets.

2. Characteristics and Structural Features

(1)Automatic detect and set bag length without manual setting on the packaging equipment touch screen

(2)Simple machine structure with flexible wheels, easy to maintain or change location. It guarantees long life span and hygienic.

(3)The single chip of main control circuit developed by our company. Digital screen and transducer control guarantees conveniently operation

(4)Double transducer control with stepless speed shift and wide adjustment, It can match well with the former working procedure of production line;

(5)Highly sensitive detector automatically and accurately monitors the whole packaging procedure.

(6)Independent temperature control guarantees beautiful and tight sealing packages.

(7)Suitable for a wide variety of flexible packing material, packing size and products.

(8)Optional device: Date printer, air charging device and servo motors

(9)Machine with a compact design, ideal for small-scale production.

(10)Cantilever design cosntruction to optimise machine hygiene and cleaning.

(11)2.5 m long infeed conveyor for packaging equipment.

(12)Top reel holder with self-centring reel fastening and braking system.

(13)Three pairs of rollers for pulling film and longitudinal seals.

(14)Rotating jaw sealing head with maximum flexibility.

(15)djustable infeed pitch for varying products

(16)Mechanic gear box to adjust the bag length

(17)Toothed shaft to configured according to product’s length

(18)Safety covers with safety micro-switches

(19)54 mm out-feed belt/finished belt of the packaging equipment

(20)Intelligent temperature control, intuitive display, easy for setting, accurate temperature

3. Optional Device of the Packaging Equipment

(1)”No product – No bag” function.

(2)Extra metre of feeding conveyor.

(3)Photocell for centring printed film.

(4)Double reel holder.

(5)Date code printers.

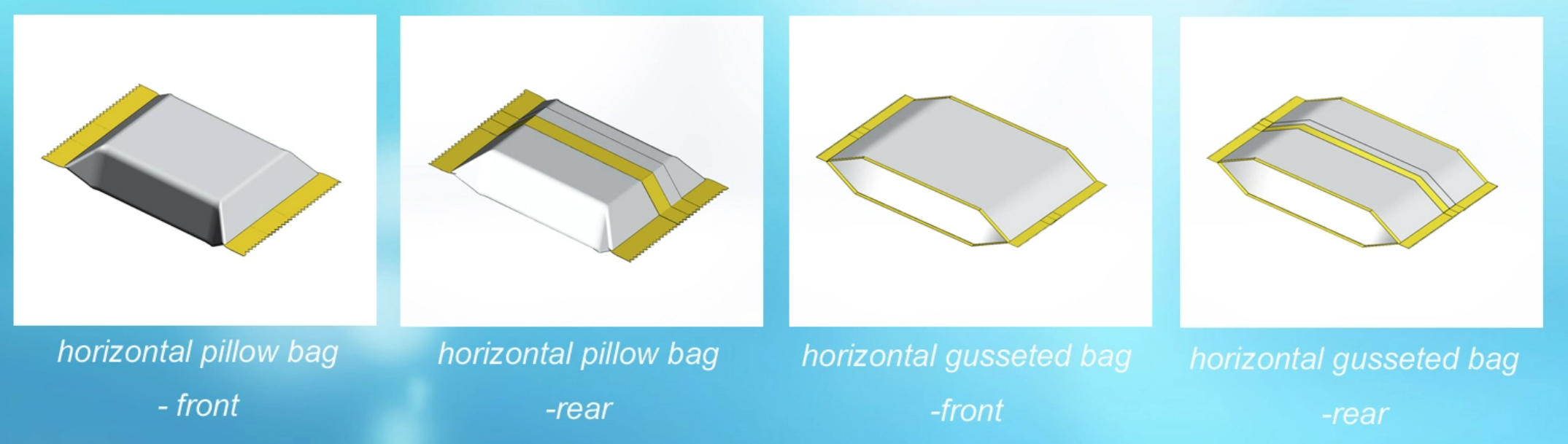

(6)Gusseting device.

(7)Zig-zag cutting knives.

4. Packing Machine Details Introduction:

A.Spool holder/ Film real support about packaging machine

The spool holder is self-centering and allows for easy film spool replacement

Automatic double spool-holders are available as an add-on option if a label applicator is not installed

B.Seal wheel about packaging machine

The electrical resistance system helps to avoid burning of the film, even when the machine is not running

The system is controlled by a digital temperature control with dual screen HMI for correcting asynchronies and reduces discrepancy to +/-2°C

The rollers resistance system is activated by solid state relays

The temperature control has multiple alarm signals to alert operators if issues arise

Greasing points are centralized for easy maintenance

The forming tunnel is universally adjustable for height and width

C.Head-cutter about packaging machine

An easy to use electric button on the HMI is used to position the product with the head-cutter

The temperature control is equipped with several alarm signals

The cutting blade is fully adjustable

Greasing points are centralized for easy maintenance

The structure of the group is coated steel and the heat points are mechanically separated in order to allow for excellent heat dispersion

The pressure dampener is adjustable by two springs

The machine is equipped with safety devices to prevent damaging the mechanics. Sensitivity can be adjusted according to the product

The controls allow for variable widths and heights of the products

D.CONTROL PANEL

E.IN-FEED CONVEYOR

The in-feed conveyor has a total length of 2.5 meters and features stainless steel lateral guides that can be easily opened and cleaned. An optional in-feed conveyor that is 1000-3000 mm is also available.

The removable pushers are made from high-quality plastic and are certified for use with food products

Product is transported by Teflon mats to avoid damages

The bottom opening of the in-feed conveyor is hinged to provide easy access for cleaning

Display

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Manufacturing Companies for Press And Seal Machine - TMZP100 Flow Wrapper Pillow Packing Machine – Temach, The product will supply to all over the world, such as: Melbourne, Croatia, Mongolia, We pay high attention to customer service, and cherish every customer. We've maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.