Popular Design for Dispersion Equipment - Vacuum Emulsifying Paste Making Machine – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Popular Design for Dispersion Equipment - Vacuum Emulsifying Paste Making Machine – Temach Detail:

The Main Toothpaste Manufacturing Processes Are As Below

A typical process could be described as follows:

The liquid ingredients are prepared first such as the water, sorbitol/glycerin.

Powdered ingredients are dry blended with others ingredients.

Next, the sweetener and preservative is added.

Premixed abrasive/filler is added with the liquid base.

Flavoring and coloring are added.

Finally, under slow speed mixing, the detergent is added to minimize foaming.

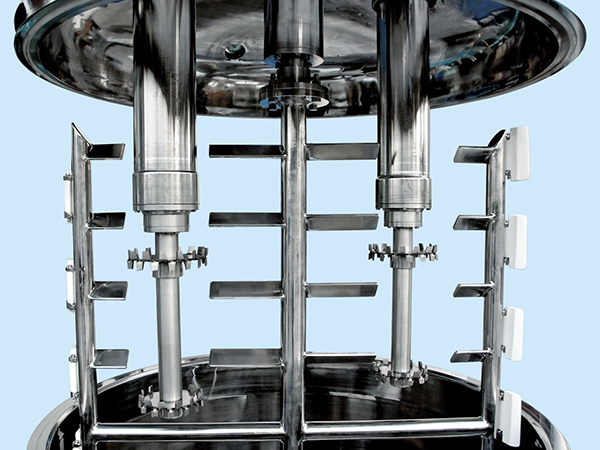

Characteristics of Our Machines

Operate under vacuum condition;

High-quality stainless steel tank with a jacket for heating or cooling;

Mid-stirring and side-dispersing, no material accumulation or dirty corners;

High-speed disperser or a high-shear homogenizer(Max 1440rpm), which mixes powder and liquid materials through high-speed rotation, and generates a turn in the paste-making pot to make the material homogeneous and delicate;

High vacuum degree of -0.095MPa, good defoaming effect;

CIP cleaning system, good and easy for cleaning;

PLC control panel, convenient and stable.

| Model | TMZG 100 | TMZG 700 | TMZG 1300 |

| Volume | 100L | 700L | 1300L |

| Power of Vacuum Pump | 3kw | 4kw | 7.5kw |

| Hydraulic Pump | 1.1kw | 1.5kw | 2.2kw |

| Lifting Height of Pot Lid | 800mm | 1000ml | 1000ml |

| Dimension(LxWxH) | 2450x1500x2040mm | 4530x3800x2480mm | 1800x3910x3200mm |

| Weight | 2500kg | 3000kg | 4500kg |

Display

Product detail pictures:

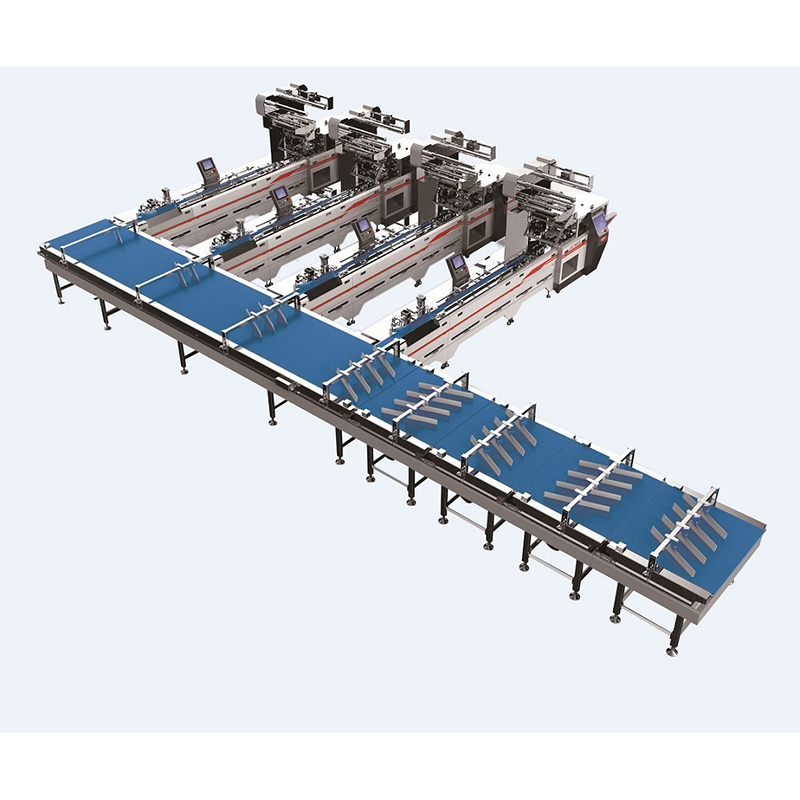

Related Product Guide:

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for Popular Design for Dispersion Equipment - Vacuum Emulsifying Paste Making Machine – Temach, The product will supply to all over the world, such as: Munich, Greece, Azerbaijan, We have more than 10 years exported experience and our products have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.