-

Big Bag Box-motion Packing Machine (Bottom Film)

Our big bag box-motion packing machine is Reciprocating Servo Packaging Machine.

It is suitable for the secondary packing of biscuits, waffles, bread, cakes, instants noodles and other regular products.

-

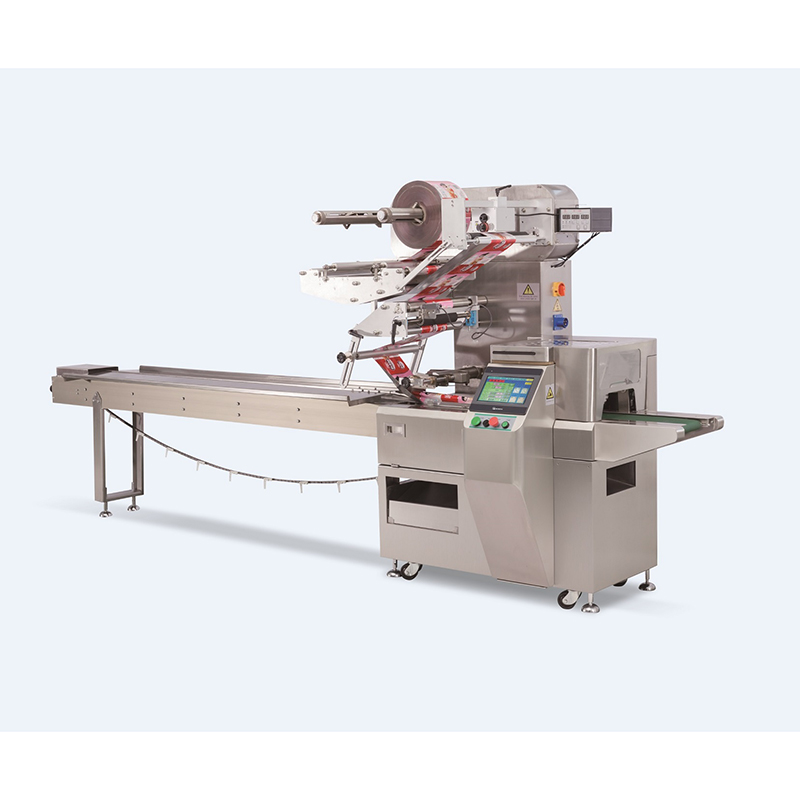

TMZP530S Flow Wrapper Pillow Packing Machine (Servo control)

This flow wrapper pillow packing machine is applicable for packing various solid regular objects, such as biscuits, cookies, ice pops, snow cake, chocolate, rice bar, marshmallow, chocolate, pie, medicine, hotel soaps, daily items, hardware parts and so on.

In-feed part can be customized according to actual needs.

It can communicate with upstream and downstream machines if needed.

-

TMZP3000S Flow Wrapper Pillow Packing Machine (Servo control, Bottom Film type)

This flow wrapper pillow packing machine is suitable for the packing of sticky, soft, long strips and other irregular items such as steamed cakes, candied fruits, wet paper towels, hardware parts, medicines, hotel disposable products, vegetables, fruits and so on.

Characteristics and structural features of this horizontal flow wrapping machine

-

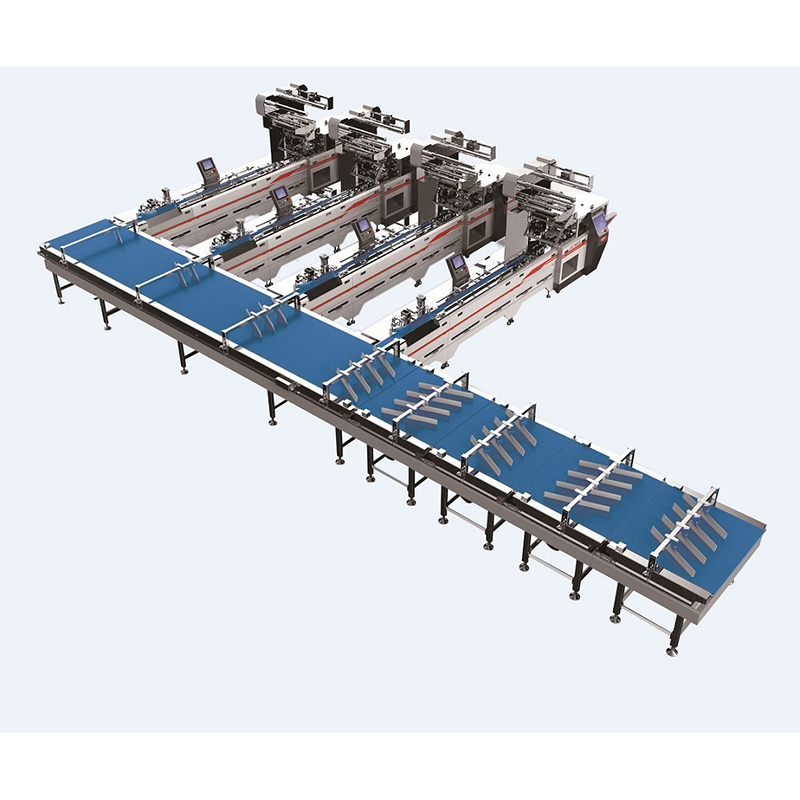

Automatic Packing Lines (Automatic feed-in system + Flow wrappers for foods)

This automatic food process and packaging system is also named sink type feeding and packing system (also named up and down packaging system), which is designed for soft products coming out from upstream machines orderly with space, like swiss roll, layer cake, and sandwich cake. The packing speed is up to 150 bags per minute with air charging device or alcohol spray device.

-

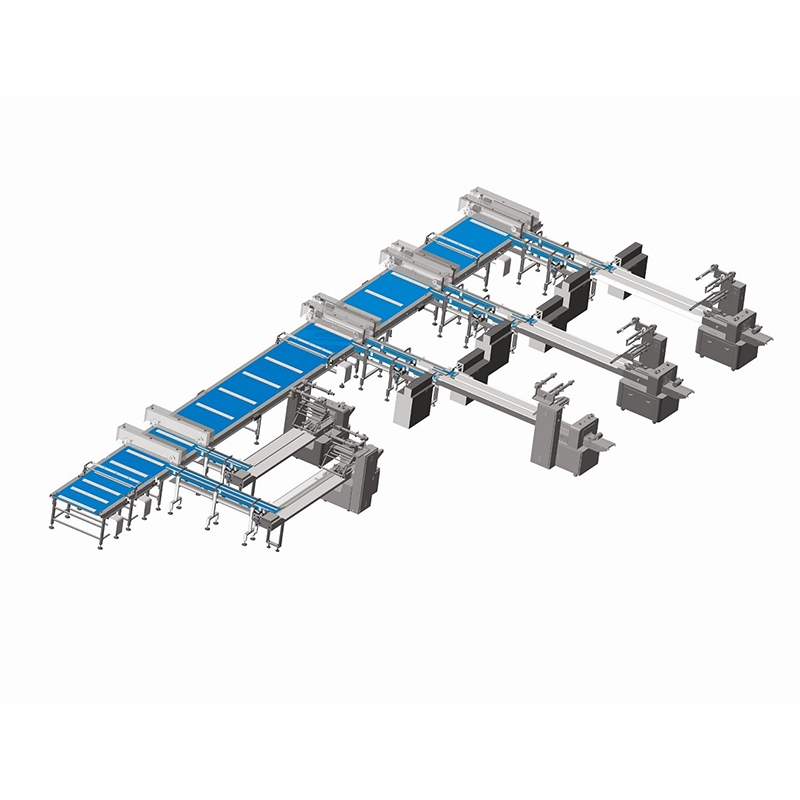

Automatic Wafer Packing Line L Type

This automatic wafter packing line is applicable for wafer and some other similar cutting products with large capacity, but in good order and regular shape. It solves the traditional problems like close distances between products, difficult direction turning, uneasy to arrange in lines, etc to achieve single or multiple packing form.

-

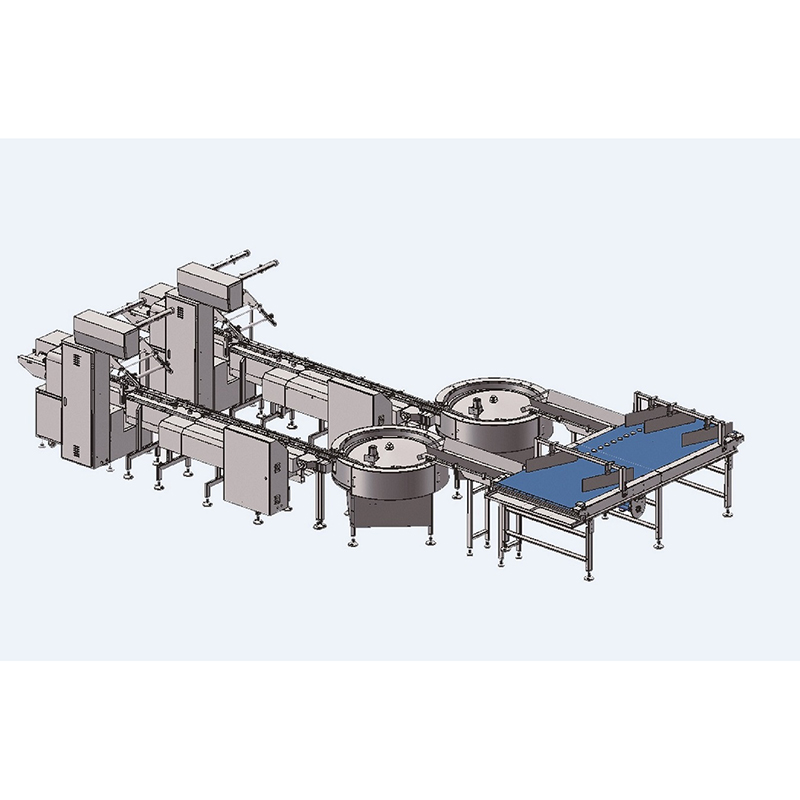

Automatic Disk Rotary Packaging Machine System

This rotary disk type flow packaging system is designed for products like egg roll, rice bar, rice roll, marshmallow, crunchy bar, nut crisp bar, wafer stick, oatmeal chocolate, flaky candies, pine cones, and pralines, cookies and other regular shape products etc. The packaging speed can be up to 350 bags per minute.

In-feed part can be customized according to actual needs.

It can communicate with upstream and downstream machines if needed.

Manual or automatic feedings are both possible.

-

TM-120 Series Automatic Food Cartoner

This food cartoning packing machine includes six parts: in-feed chain part, carton suction mechanism, pusher mechanism, carton storage mechanism, carton shaping mechanim and output mechanim.

It is suitable for big size secondary packaging for busicuits, cakes, breads and products of similar shapes.

-

TM-120 Series Automatic Pharmaceutical Cartoner

This medicine cartoning packing machine mainly includes seven parts: medicine in-feed mechanism, pharmaceutical in-feed chain part, carton suction mechanism, pusher mechanism, carton storage mechanism, carton shaping mechanim and output mechanim.

It is suitable for products like pharmaceutical tablets, plasters, masks, foods, and similar shapes, etc.

-

TM-120 Series Automatic Cosmetics Cartoner

This bottle cartoning packing machine mainly includes eight parts: bottle sorting mechanim, automatic bottle lay-down mechanism, bottle in-feed chain part, carton suction mechanism, pusher mechanism, carton storage mechanism, carton shaping mechanim and output mechanim.

It is suitable for products like cosmetics, medicine bottles, eyedrops, perfumes and products which are of similar cylinder shapes.

-

Handmade Soap Cutter

It is an easy control pneumatic string type cutter for handmade/ home made soap making, either cold processing or glycerin soaps.

It can be used for cutting big soap blocks into single soap bars, efficient and stable.

Adjustable soap width, handle control.

Convenient for operation, simple for adjustment and maintenance.

Video on Youtube: https://youtube.com/shorts/Z50-DjVJ3Fs

-

Lab Scale Emulsifying Mixer Homogenizer

This Lab Scale Small Size Vacuum Emulsifying Mixer Homogenizer is specially designed for small batch test or production use with it’s smart structure and high efficiency advantages, mainly for laboratory use and small batch production.

This vacuum emulsifying machine includes homogenizing emulsifying mixing tank, vacuum system, lifting system and electrical control system.

-

Vacuum Homogenizing Emulsifying Mixer

Our Vacuum Homogenizing Emulsifying Mixing system is a complete system for making viscous emulsion, dispersion and suspension in small and large scale production, which are widely used for cream, ointment, lotion and cosmetics, pharmaceutical, food and chemical industries.

The advantage of the vacuum emulsifier is that the products are sheared and dispersed in a vacuum environment to achieve the perfect product of defoaming and delicate light feeling, especially suitable for good emulsion effect for materials which are of high matrix viscosity or high solid content.