Short Lead Time for Ultrasonic Tooling - Jacketed Stainless Steel Reactor – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Short Lead Time for Ultrasonic Tooling - Jacketed Stainless Steel Reactor – Temach Detail:

Details

It is composed of SUS304 or SUS316L body and jacket. We have different jackets: standard jacket, outer circular pipe jacket and Milo plate honey net jacket. This reactor can be heated or cooled.

Mirror polish for inner surfaces and, no dead cleaning angles. Closed Seal design ensures materials working in asepsis condition.

The conic tip processed by spinning pressure, meeting GMP standard.

The agitator adopts sanitary mechanical seal.

Insulation parts are of polyurethane or alumina silicate.

Connection joints are of ISO standard, with quick open clamp.

Outer surface adopts high quality polishing, sand- blast, dull polish or cold rolled original color subtopics, flexible for different using occasions.

This reactor is equipped with asepsis respirator, CIP cleaning spray head, view glass, and flange quick open manhole, easy and convenient for operation.

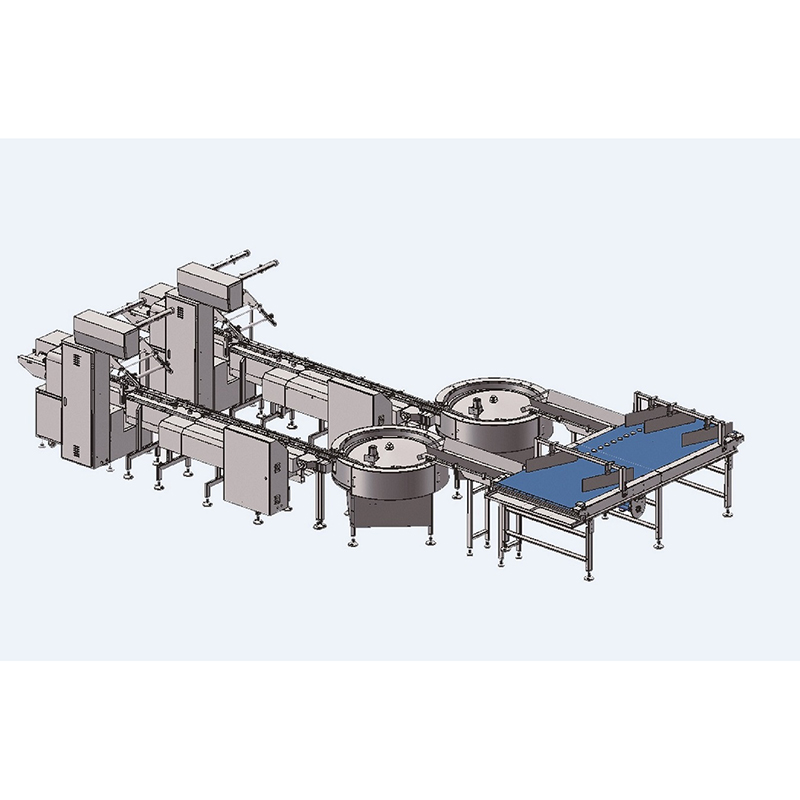

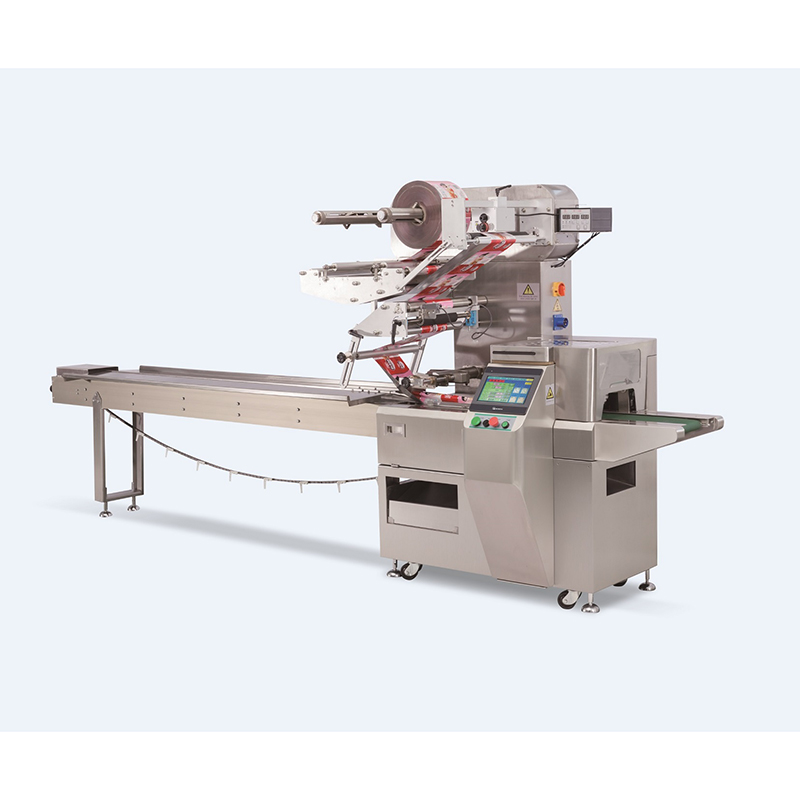

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Short Lead Time for Ultrasonic Tooling - Jacketed Stainless Steel Reactor – Temach, The product will supply to all over the world, such as: Wellington, Qatar, Indonesia, We follow up the career and aspiration of our elder generation, and we are eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.