Special Design for Box Packaging - Automatic Packing Lines (Automatic feed-in system + Flow wrappers for foods) – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

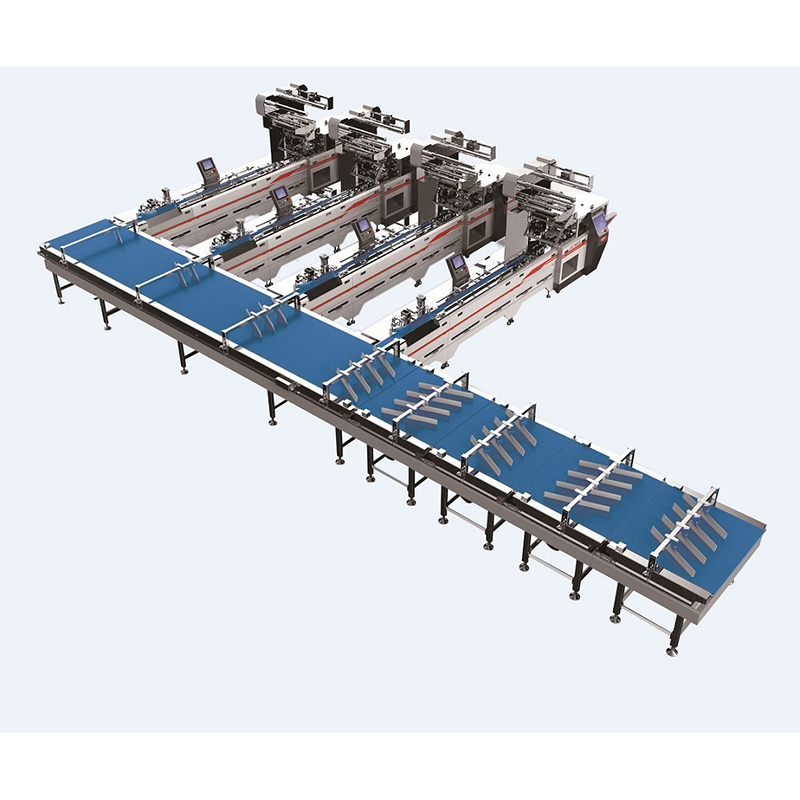

Special Design for Box Packaging - Automatic Packing Lines (Automatic feed-in system + Flow wrappers for foods) – Temach Detail:

Product Detail

1. The automatic feeding system is selected according to the products‘ incoming condition and the packing requirements. Products feed-in conditions includes: material characteristics, processing technology, capacity, status, arrangement direction, etc. The packing requirements includes: single, multi-pack assembly, adding support box, positive and negative, etc.

2. According to the stable operation speed of different feeding packing line, to match the demand of customer’s production capacity, design the scientific, reasonable and efficient planning scheme.

Characteristics

1. The automatic feeding system is designed by professional industrial appearance designers. According to the aesthetic viewpoint and principle, the transmission and functional structure are further optimized, the aesthetic degree and operability are fully considered, and the high-end brand image is molded.

2. The separation arraying conveyor can realize the orderly arrangement of products, high-speed and stable, and easy to operate.

3. The conveyer belt of automatic feeding system can disassemble and disassemble quickly without tools. The bottom and interface of conveyor belt are equipped with slag slot, which is convenient to maintain and clean equipment, save time and effort.

4. The whole line selects high-quality food grade conveyor belt.

5. Control system uses high-quality electrical components, equipped with servo motor, PLC control, touch screen operation display, good man-machine interface, simple operation, intuitive, convenient.

Equipment Advantage

1. The automatic feeding system normal combined by separation arraying conveyor, automatic feeding system and automatic packing machine, different types of systems, with corresponding alternative functions to meet customer packing needs.

2. The working speed of automatic feeding system is 100-600pcs/min by single kind product.

3. The automatic feeding system power is about 1.2kW.

Display

Product detail pictures:

Related Product Guide:

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for Special Design for Box Packaging - Automatic Packing Lines (Automatic feed-in system + Flow wrappers for foods) – Temach, The product will supply to all over the world, such as: Malawi, Florence, El Salvador, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, please feel free to contact us. We would love to provide you with further information.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.