TM-120 Series Automatic Cosmetics Cartoner

Short Description:

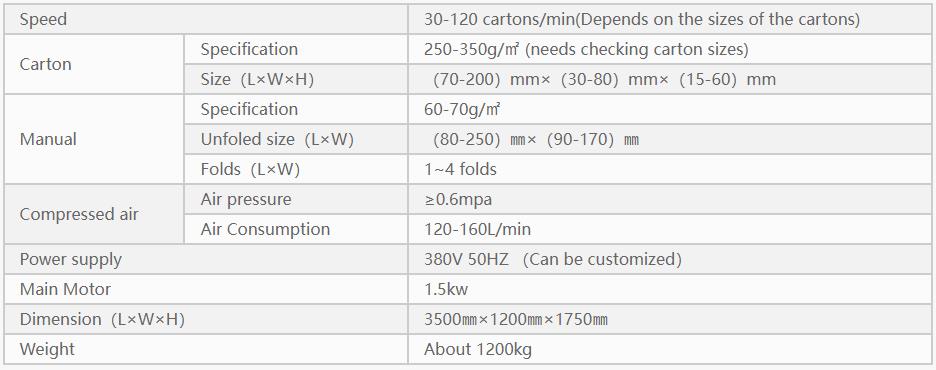

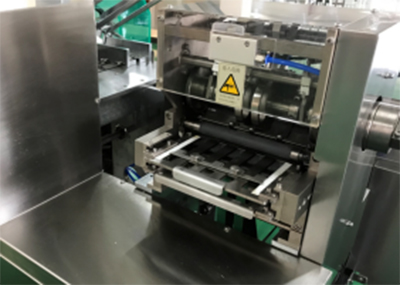

This bottle cartoning packing machine mainly includes eight parts: bottle sorting mechanim, automatic bottle lay-down mechanism, bottle in-feed chain part, carton suction mechanism, pusher mechanism, carton storage mechanism, carton shaping mechanim and output mechanim.

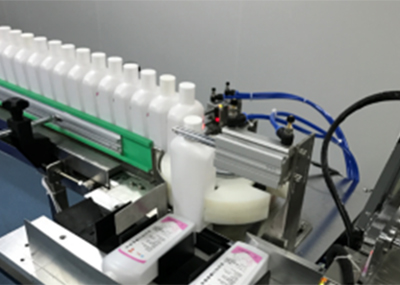

It is suitable for products like cosmetics, medicine bottles, eyedrops, perfumes and products which are of similar cylinder shapes.

Product Detail

Product Tags

Product Detail

This cartoner automatically feeds in the bottle products or similar products and cartons, sucks and folds the manuals, opens the cartons, pushes the products into the cartons, prints the codes, seals the cartons and transfer the finished products out.

There are two types of sealing for the cartons: tucker type or glue type, which can be chosen by customers’ actual needs.

The feeding part can be customized according to actual needs.

This machine can be used independently or with a filling production line, communicating with upstream and downstream machines together.

Characteristics

1.PLC control with HMI, easy for operation and maintenance.

Operators can check the production status, set the parameters according to actual production needs. When there’s faulty alarm, the faulty reason can be shown on the HMI for easy analyse.

2.The main motor speed is controlled by VFD. VFD controls the incremental angle encoder, which acts instead of traditional cam mechanism, more preciser for positioning.

3.This machine is equipped with alarm function.

If the operation is wrong, it will stop automatically. When the machine runs exceeding or below the set value, it will automatically alarm. It is equipped with E-stops. When the E-stop buttons are pressed, all pneumatic and electric control functions will be turned off. In addition, In addition, an overload torque protector is designed at the power input part for stopping the machine immediately when it encounters overload during operation. Moreover, the cartooning packing machine is equipped with plexiglass safety cover to protect the operators from possible hurts .

4.Stable running and reliable performances

Photoeyes and PLC are designed and mounted for stable running and high efficiency. The whole machine is controlled by the programmable logic controller (PLC) in a centralized manner to realize the coordinated action of the whole machine. If there is an error in the current station, the photoelectric induction device will send a signal, and the downstream station will stop working, and an alarm will occur. If there is an error in the work of the rear station, the photoelectric induction device will send a signal, and the upstream station will stop working. Therefore, the machine has simple structure and reliable operation, ensuring product quality and improving production efficiency.

5.Branded components are used for good performance of the machines.

Technical Characteristics

Part Introductions

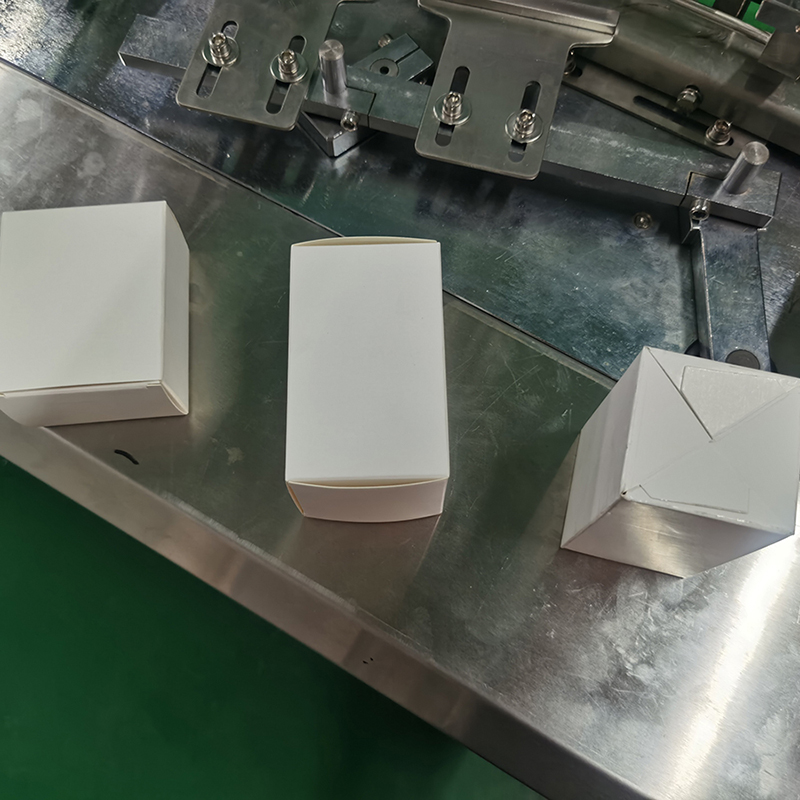

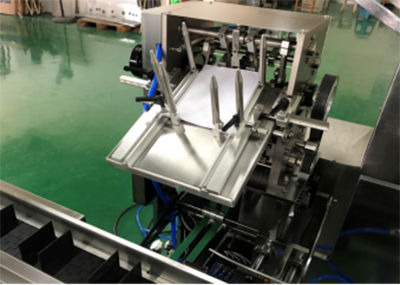

Carton Storage (About 400pcs of cartons)

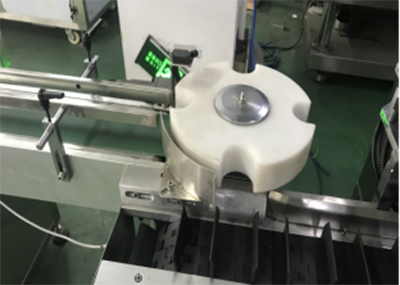

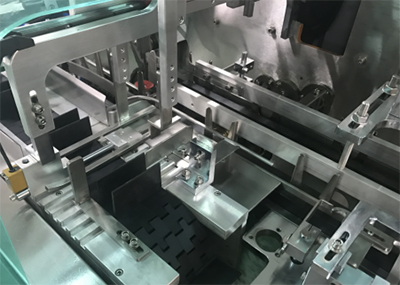

Bottle Pusher Mechanism

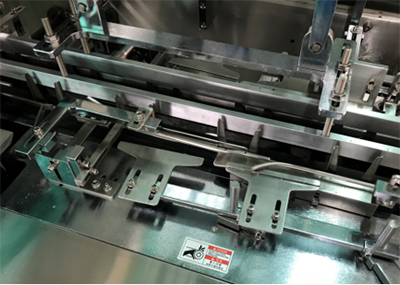

Carton Transmission Chain

Tucker Mechamism

Ejection Mechanism for Empty Boxes

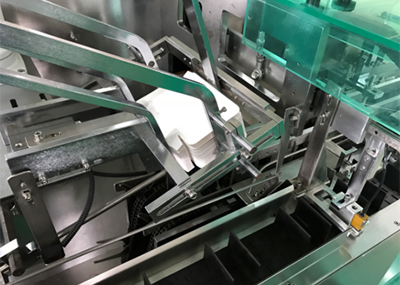

Manual Folding and Feeding Mechanism

Bottle Feeding Mechanism